Our research interests are in the broad area of multi-physics theoretical, computational, and experimental mechanics of materials, with a focus on the development of continuum mechanics theories. In energy-storage materials, our work focuses on investigating two important concepts:

– How the mechanical behavior of a systems affects its energy storage behavior, and vice versa; and

– How the coupling between mechanics and chemistry can be harnessed to improve the energy storage performance of a material system.

Ongoing Projects:

Next-Generation High-Density Energy Storage

Towards the development of next-generation energy storage devices, the M3Lab is currently engaged in a number of research projects where electro-chemo-mechanical coupling plays a critical role on improving electrochemical performance.

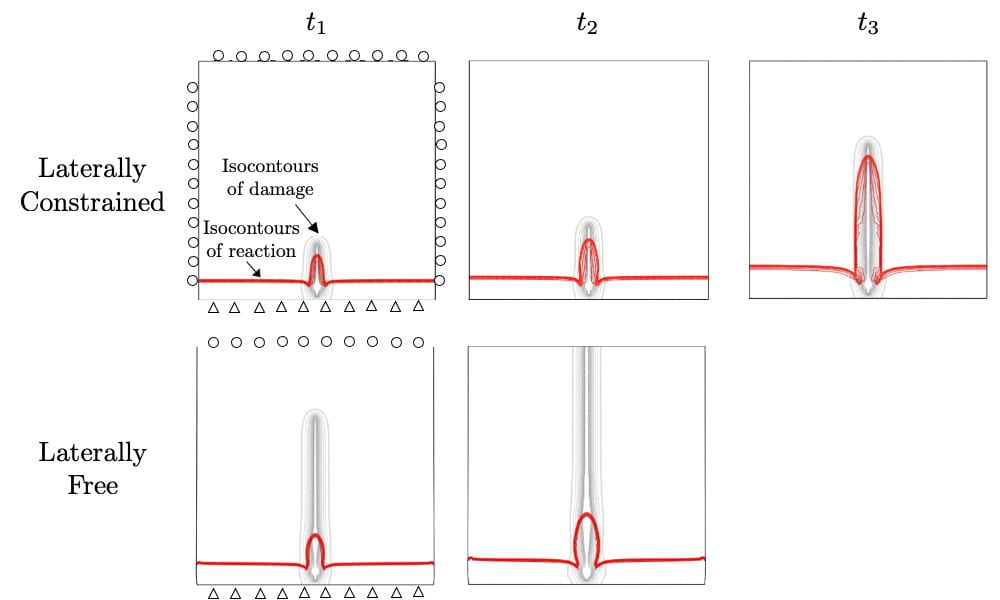

Continuum Electro-Chemo-Mechanics with damage. Modeling Li-Metal Filament Growth in All-Solid-State Batteries

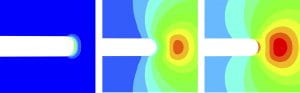

The growth of Li-metal filaments through solid-state electrolytes is a critical issue hindering the commercialization of all-solid-state batteries. In this research project we develop a thermodynamically consistent phase-field theory which coupled electrodeposition of Li-Metal with the underlying fracture of the solid-state electrolyte host. The theory develops a novel multi-phase-field approach for describing the concurrent phenomena of fracture and electrodeposition and captures the critical role mechanics plays in the evolution and growth of Li-Metal filaments. Info/Videos/Publications.

Funding: NASA

Publications: Bistri and Di Leo, JMPS, 174, 2023

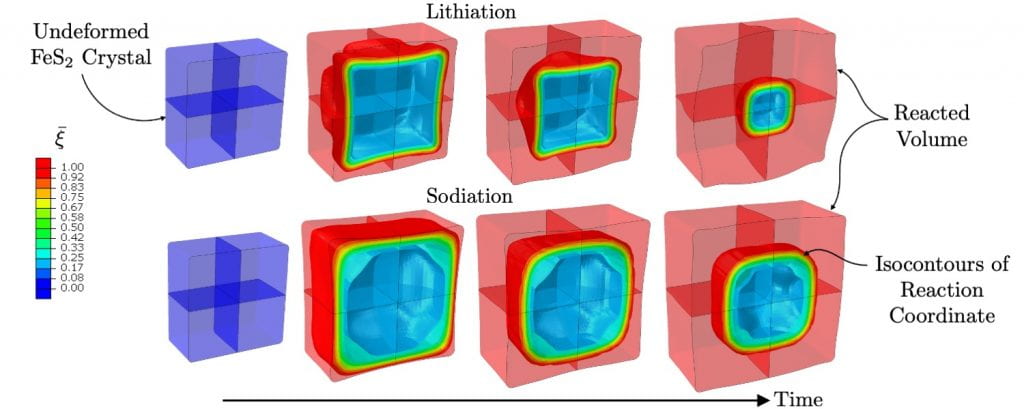

Continuum Theory for Diffusion-Reaction-Deformation in Solids

The coupling between mechanical deformation and electrochemistry in the presence of sharp interface electrochemical reactions is critical in a number of components of next-generation and all-solid-state batteries. In this research projects we develop a thermodynamically consistent phase-field finite strain theory for problems which couple transport of species in a host material, sharp interface reactions, mechanical deformation and stress. Info/Videos/Publications.

Funding: National Science Foundation, CMMI, Mechanics of Materials and Structures (MOMS) Program.

Publications: Afshar and Di Leo, JMPS, 151, 2021

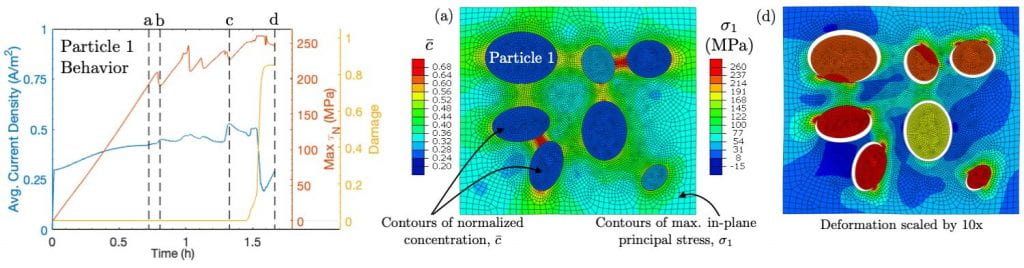

Chemo-Mechanical Behavior of Composite Electrodes

This research effort focuses on capturing the chemo-mechanical multi-particle behavior of composite electrodes including damage. In particular, we are working on modeling the local current densities which vary across the surface of active particles during charging. This depends on the local, stress-coupled, electrochemical potential and is also affected by interfacial damage.

Funding: National Science Foundation, CMMI, Mechanics of Materials and Structures (MOMS) Program. Info/Videos/Publications.

Publications: Bistri and Di Leo, JECS, 158(3), 2021

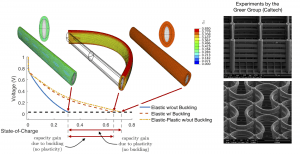

Nano-Architected Electrodes

This research project aims to develop the necessary numerical tools for modeling the electro-chemical performance of nano-architected electrodes, including their performance when undergoing elastic instabilities such as buckling. Our fully-coupled diffusion-deformation theory — and numerical implementation — is used to predict the electrochemical performance of a given nano-architecture as well as predict its mechanical performance and resilience during lithiation. Info/Videos/Publications.

Collaborators: The Greer Group at Caltech who perform all of the experiments.

Funding: National Science Foundation, CMMI, Mechanics of Materials and Structures (MOMS) Program.

Publications: Xia et al, Nature, 573, 2019. Xia et al., ACS Energy Lett., 1, 2016.

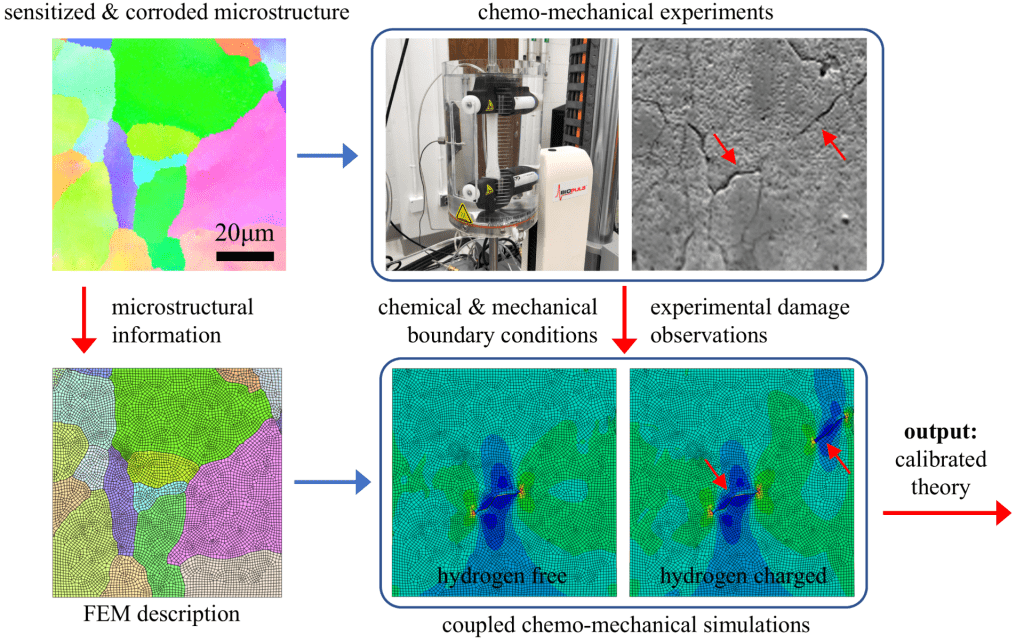

Environmental Induced Degradation of Al-Mg Alloys

This research project aims to develop an experimentally validated numerical framework for understanding and predicting microstructural effects on environmental induced cracking (EIC) of Aluminum Magnesium alloys. We are developing a fully-coupled deformation-diffusion theory for hydrogen migration within the microstructure of the alloys accounting both for bulk grain and grain boundary chemo-mechanical behavior. Along with detailed experiments the framework will be numerically validated and used to analyze the relevant microstructural descriptors which yield alloys with improved EIC behavior.

Collaborators: The Kacher Lab at Georgia Tech is performing all of the experimental work.

Funding: US Air Force Academy’s Center for Aircraft Structural Life Extension (CAStLE)

Robotic Landing Gear for Rotorcraft

This project involves the design, manufacturing, and flight testing of a robotic landing gear (RLG) concept for rotorcraft. In collaboration with Boeing, the RLG system is being developed for a ~400lb Unmanned Aerial Vehicle. Through this project the team developed a novel four-bar cable-driven leg mechanism as well as novel ground contact sensors based on rubber encapsulated pressure sensors. Both technologies which are currently being patented. Info/Videos/Publications.

Collaborators: Mark Costello (GT), Julian J. Rimoli (GT).

Funding: DARPA Tactical Technology Office (TTO), Air Force Research Laboratory (Concluded),

Boeing/Mesa. (Concluded), Air Force Phase I STTR (Concluded),

Army SBIR Phase I (Current), Air Force STTR Phase II (Current)

Past Projects:

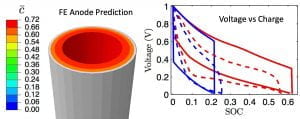

Amorphous Silicon Anodes

Amorphous Silicon Anodes

In this work we formulate, numerically implement, and calibrate, a fully-coupeld diffusion-deformation theory for amorphous Silicon anodes. The theory accounts for transient diffusion of Li and accompanying large elastic-plastic deformations. We show that our numerical simulations are in good agreement with expereimntally-measured voltage vs. state-of-charge (SOC) behavior. Info/Videos/Publications

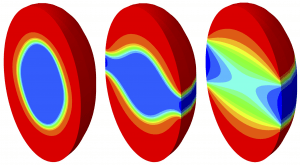

Phase-Separating Cathode Materials

Phase-Separating Cathode Materials

Unified framework of balance laws and thermodynamically-consisten constituve equations which couple Cahn-Hilliard-type species diffusion with large elastic deformations of a body. The developed numerical tool is used to study the combined effects of diffusion and stress on the lithiation of spheroidal-shaped particles. Info/Videos/Publications

Hydrogen Transport in Metals

Hydrogen Transport in Metals

We formulated a thermo-chemo-mechanically coupled-theory which accounts for diffusion of hydrogen and large elastic-plastic deformations of metals. The theory accounts for the trapping of hydrogen at microstructural defects and places the notion of an equilibrium between trapped and diffusing hydrogen within a thermodynamically-consistent framework. Info/Videos/Publications

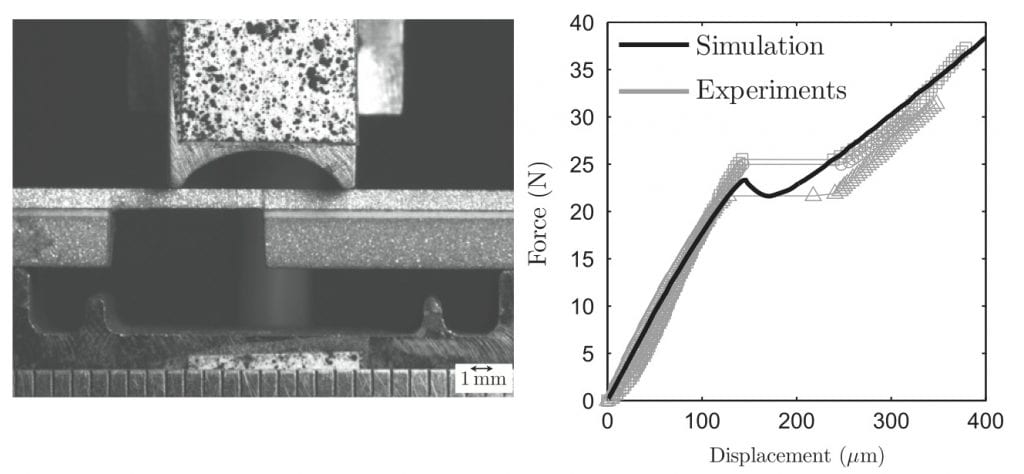

Characterizing Interfacial Failure in Thermal Barrier Coatings (TBCs)

In this work, we developed an experimental-plus-simulation approach to determine the relevant material parameters appearing in a traction-separation-type law for modeling delamination failures in TBCs. Info/Videos/Publications.