Overview

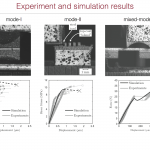

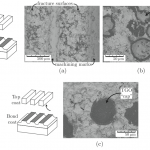

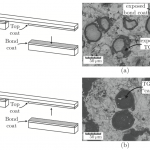

One application of thermal barrier coatings (TBCs) is in their use on turbine blades of land-based turbines used in the production of electricity. The ability to characterize the interfacial delamination properties of the TBC is of great technological importance for lifetime assessments of such coatings under service conditions. In this work, we developed an experimental-plus-simulation-based approach to determine the relevant material parameters appearing in a traction-separation-type law which should be useful for modeling delamination failures in TBCs. We combine load-displacement measurements obtained from (i) a standard tension experiment; (ii) a novel shear experiment; and (iii) a novel asymmetric four-point bending mixed-mode experiment, with simulations in order to extract the requisite material parameters for this traction-separation model. The methodology was applied to a TBC system (air-plasma-sprayed YSZ top-coat and MCrAlY bond-coat) which was isothermally exposed to air at 1100◦C for 6 days prior to testing.

Publications

Di Leo C.V., Luk-Cyr, J., Liu, H., Loeffel, K., Al-Athel, K., and Anand, L. (2014). A new methodology for characterizing traction-separation relations for interfacial delamination of thermal barrier coatings. Acta Materialia, 71, 306-318. [hmtl]